FINISHING PROCESSES

Assembly Solutions

Alutrim offers several assembly options including crimping, injection molding, adhesive, tri-lam, and toy-tabs. In addition to these bonding techniques, we also offer finishing and assembly operations.

FINISHING PROCESSES

Finishing & Assembly

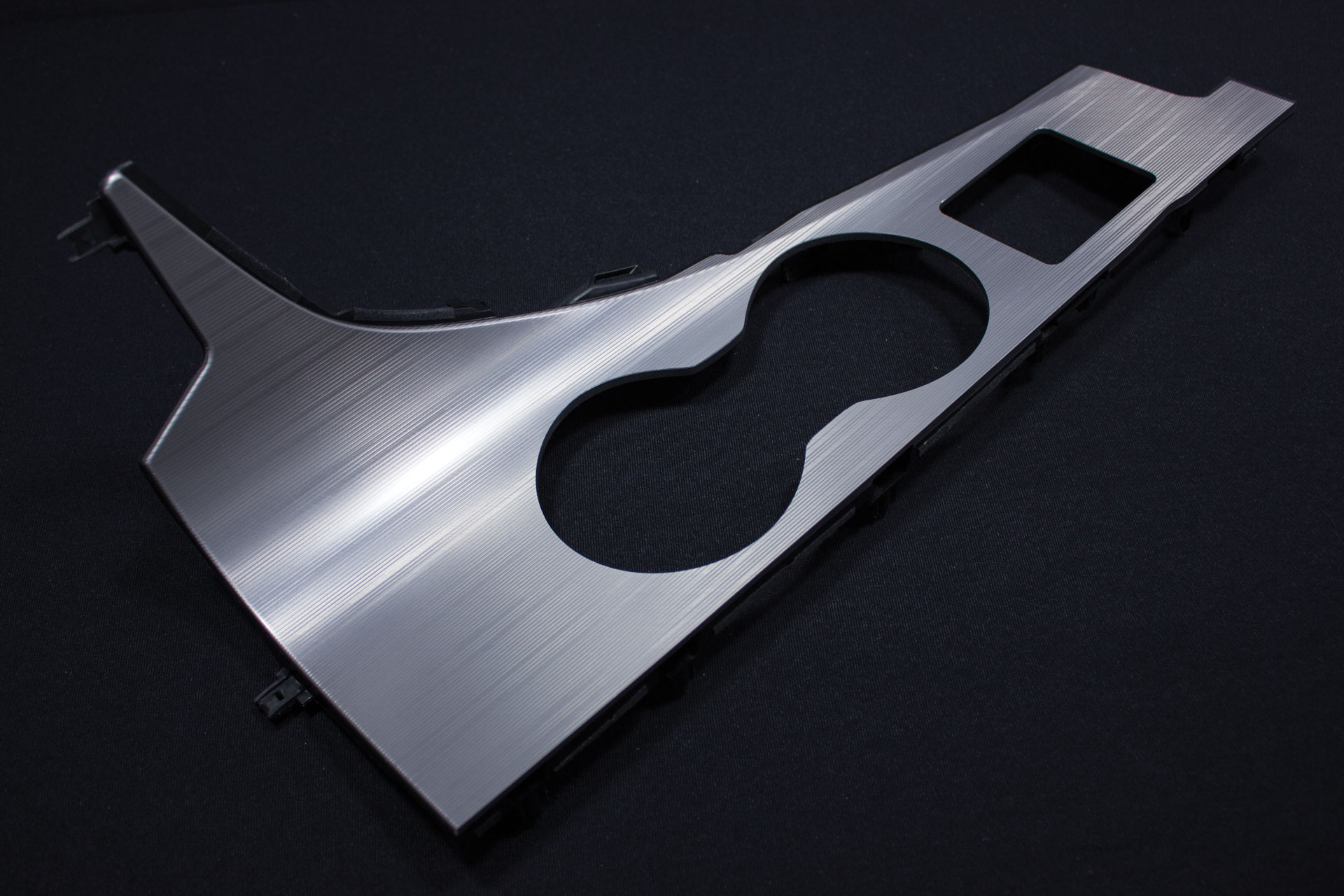

Alutrim offers modular assembly of in–house manufactured and purchased components.

- Precision milling (3-Axis and 5-Axis CNC machining)

- Sonic and heat stake welding

- Assembly of aluminum or stainless to a substrate

- Application of adhesives, tapes and masking

- Installation of specialty fasteners, switches and lighting components

- Labeling and sequencing

FINISHING PROCESSES

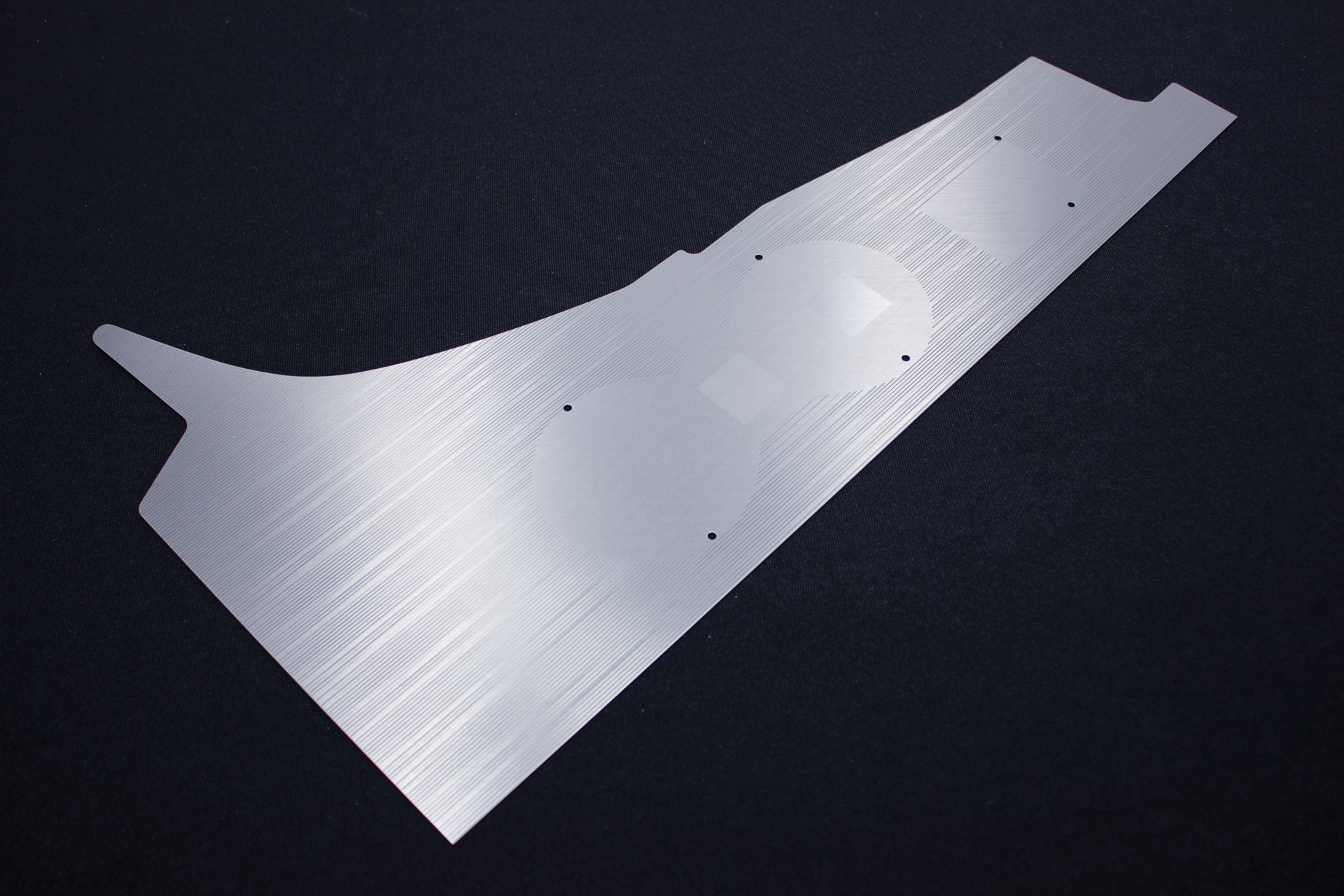

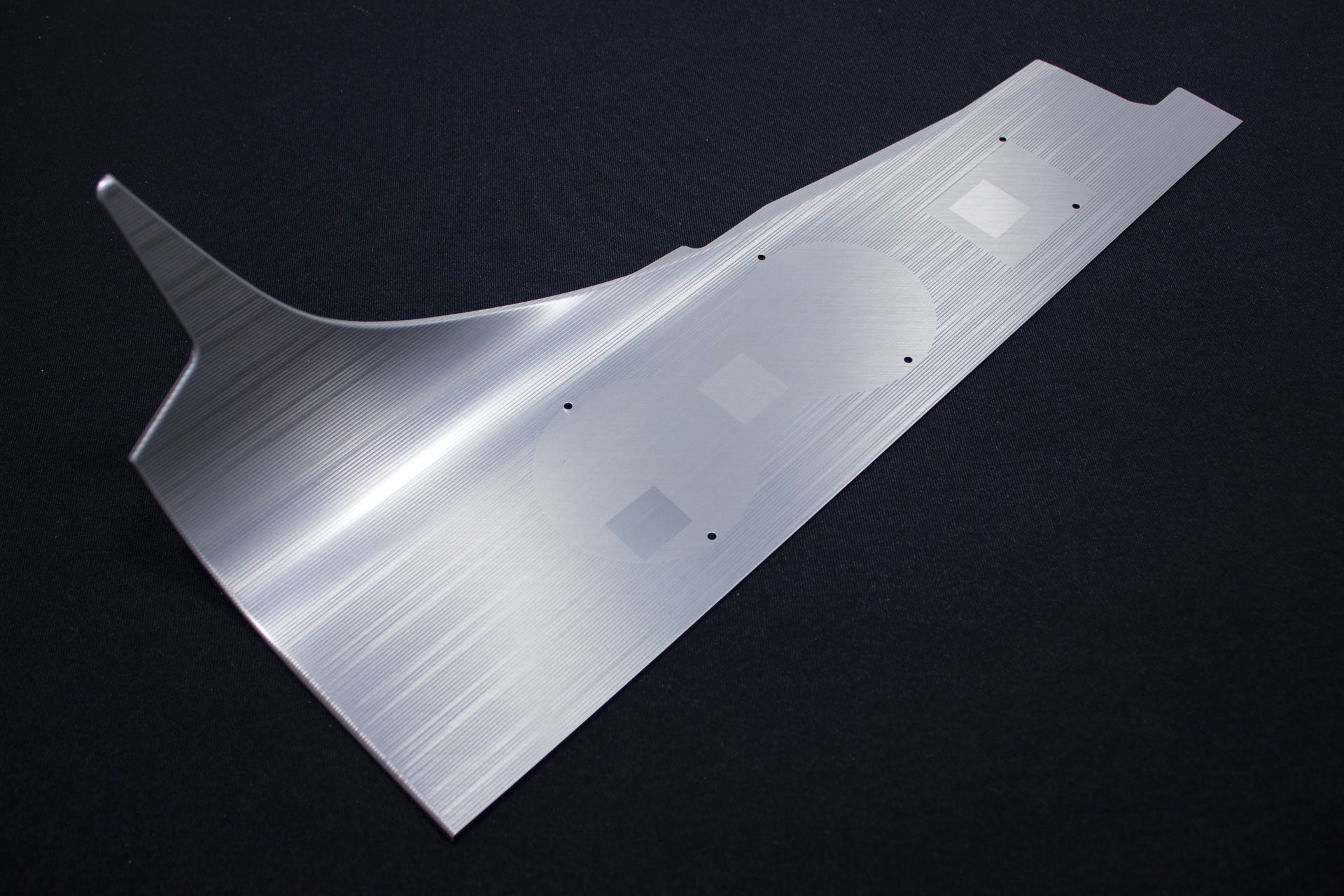

Milling

Alutrim offers milling services for a wide variety of parts utilized throughout interior and exterior trim components.

- Precision milling (3-Axis and 5-Axis CNC machining)

- CNC milling for clean, sharp edges

- Superior dent resistance

- Wide range of reverse side features

- No additional assembly tooling requires

FINISHING PROCESSES

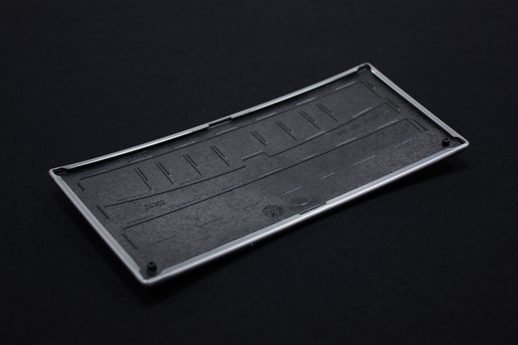

Insert Molding

Insert molding, or back molding, is accomplished through molding plastic behind a formed aluminum part. This is best for parts that have hidden edges and need high impact resistance.

- CNC milling for clean, sharp edges

- Superior dent resistance

- Wide range of reverse side features

- No additional assembly tooling requirements

FINISHING PROCESSES

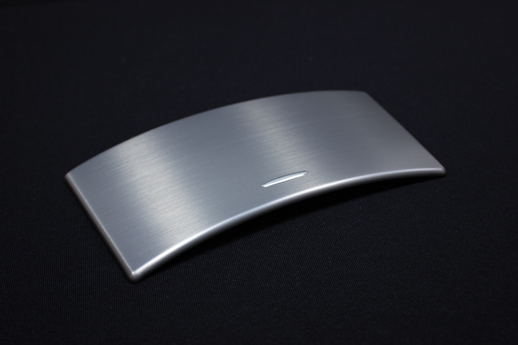

Crimping

Crimping wraps the formed aluminum sheet around the plastic carrier. This is best used for parts with visible edges.

- Design flexibility

- Complete coverage

- Strong mechanical attachment

- Reduced tooling

- Cost effective